When you’re battling saltwater’s relentless attack on your boat, you need a strategy that goes beyond the basics. It’s not just about giving the hull a good rinse; it’s about understanding how each component interacts with the harsh marine environment. Have you considered the role of sacrificial zinc anodes and how often you should replace them? Or the unseen impact of salt on your engine’s efficiency?

Every detail counts when it comes to maintaining your vessel’s integrity. Let’s explore practical tips that can safeguard your investment and keep your boat sea-ready for years to come.

1. Keep it Clean

To prevent saltwater corrosion, thoroughly wash your boat with soap and freshwater after each trip. This essential boat maintenance step helps protect your investment from the harsh effects of saltwater.

Focus on effective washing techniques, as merely hosing down the boat isn’t enough. Use good quality soap and fresh water to cleanse every surface, ensuring you reach all the nooks and crannies.

Freshwater is vital because it rinses away salt deposits that can lead to corrosion. Metal components like railings and hinges are particularly susceptible.

2. Keep it Protected

After meticulously cleaning your boat, protecting it from further exposure is your next step to prevent saltwater corrosion.

Start with cover maintenance; always dry your boat thoroughly before applying a full cover. This practice helps with moisture control, preventing water buildup that can lead to corrosion. Invest in high-quality, custom-made covers that fit snugly and shield against environmental factors like UV rays and rain.

Choose a dry and sheltered location for boat storage. If storing outdoors, ensure your boat is elevated to avoid water pooling.

Consider applying protective coatings to exposed metal surfaces, which will offer a barrier against the salty air. Regularly inspect these coatings for wear and reapply as needed.

3. Mind Your Zincs

Identify all the sacrificial zinc anodes on your boat, as they’re crucial for preventing galvanic corrosion.

Zincs are the first line of defense in corrosion prevention techniques. They deteriorate instead of your boat’s metal parts, sparing your engine and hull from the damaging effects of galvanic corrosion.

Common zinc anode locations include the engine lower unit, transom, and running gear. Regularly check these spots to see if a zinc anode replacement is necessary.

Consult your boat’s manual for exact zinc anode locations. For effective maintenance scheduling tips, inspect your zincs every few months and replace them when they’re roughly half eroded.

Don’t skip this step—neglecting zincs can lead to costly repairs and reduced vessel longevity.

4. Lubricate All Parts

Once you’ve ensured your zincs are in good condition, focus on lubricating all moving parts to prevent rust and ensure smooth operation. Proper lubrication techniques are essential for corrosion prevention and maintaining your boat’s performance. Regular mechanical inspections should be part of your maintenance schedules to identify areas needing attention.

Consider these key areas for lubrication:

Steering and tilt tubes: Apply marine grease for smooth movement.

Trailer wheel bearings: Use the appropriate grease types to avoid breakdowns.

Engine trim mechanisms: Keep them lubricated for reliable function.

Gimbal bearings: Essential for sterndrive boats, require regular greasing.

Metal latches and hinges: Use moisture-displacing lubricants to prevent rust.

5. Protect Your Engine

To safeguard your boat’s engine, use a high-quality marine fuel additive to stabilize the fuel during storage. This step is crucial for maintaining fuel stability and preventing engine issues.

Regular engine maintenance is essential; inspect and replace worn components to ensure your engine runs smoothly. Corrosion inhibitors play a vital role in protecting metal parts from saltwater damage, so apply them diligently.

Also, pay attention to battery care. To maintain electrical integrity, keep battery terminals clean and free from corrosion. Check connections regularly and apply protective sprays to prevent damage.

6. Check Power Systems

Regularly inspect your boat’s power systems to ensure all battery terminals and connections are clean and corrosion-free. Battery maintenance is crucial for corrosion prevention and efficient power management.

Begin by thoroughly cleaning the terminals using a wire brush to remove any buildup. Then, conduct a connection inspection to identify any loose or damaged cables. Properly maintained batteries ensure reliable performance and longevity.

Consider these essential steps:

Clean terminals: Remove corrosion with a wire brush.

Apply protective spray: Use battery terminal spray to prevent future corrosion.

Inspect cables: Check for wear or damage; replace if necessary.

Secure connections: Ensure all connections are tight and intact.

Regular checks: Schedule consistent inspections to catch issues early.

7. Inspect Hidden Areas

Dive into hidden areas of your boat to uncover potential corrosion issues before they escalate into costly repairs.

Start by checking under seats, hatches, and storage compartments for hidden corrosion that could compromise your vessel’s integrity.

Pay special attention to marine electronics, ensuring connections are corrosion-free and secure.

Implement effective storage solutions to keep moisture away from sensitive areas.

Regularly inspect wiring bundles and bus bars, applying protective coatings where necessary to prevent damage.

Consistent maintenance routines, including these inspections, will help you catch problems early.

Don’t overlook areas like the steering helm or beneath deck panels, as these spots often conceal corrosion.

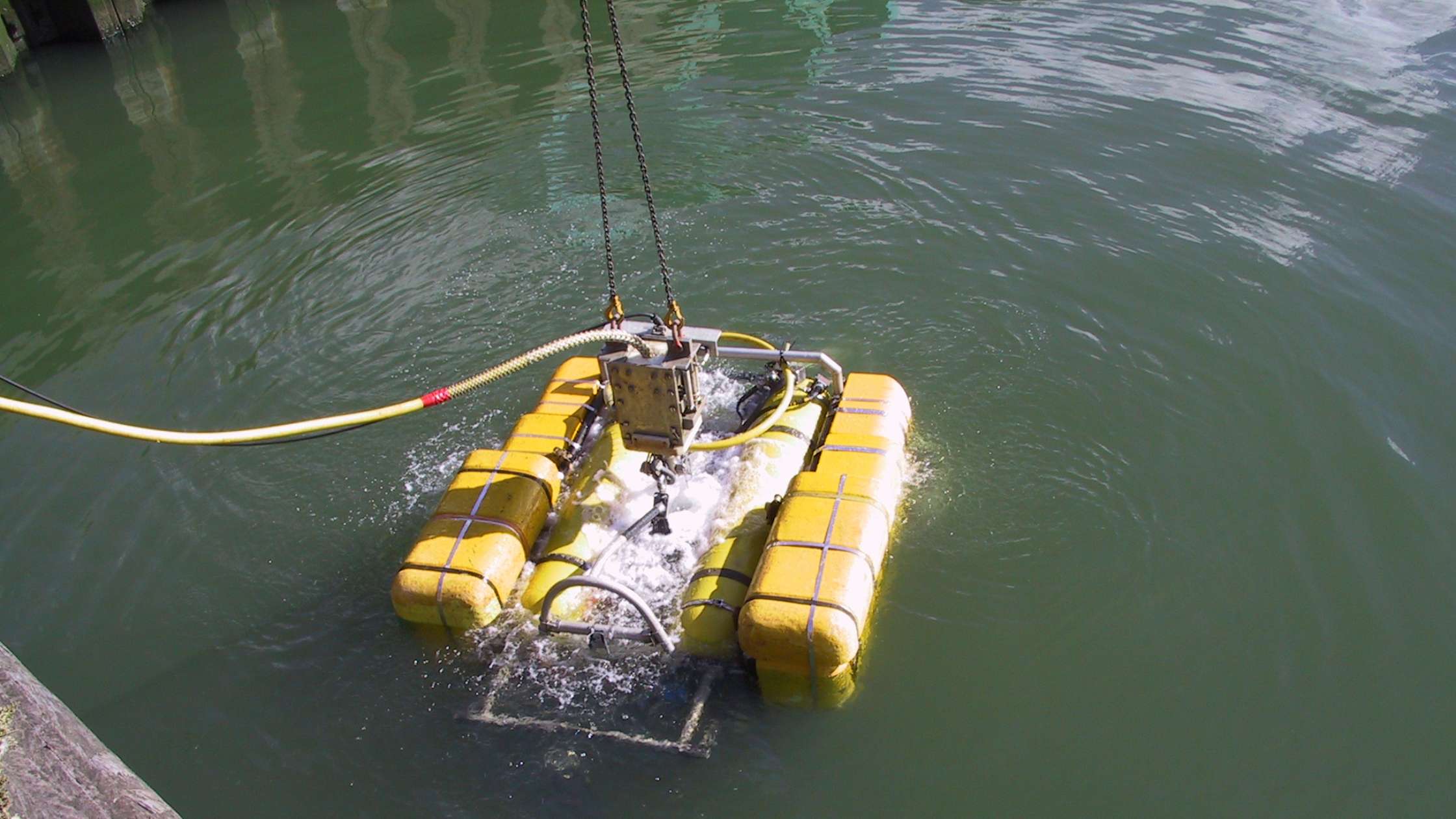

Hull2Prop: Specialists in Underwater Maintenance Services

At Hull2Prop, we understand the challenges of maintaining your vessel in saltwater environments. Our specialized underwater maintenance services are designed to combat corrosion and ensure your boat remains in peak condition.

From thorough cleaning and inspection to the replacement of critical components like zincs, we provide the vigilance your boat deserves. Our experienced team treats every maintenance task with the utmost care, safeguarding your engine and power systems from the corrosive elements of the sea.

Trust Hull2Prop to help you navigate the waters of boat ownership and preserve your vessel’s legacy for years to come.